SINO melt blown fabric mold, with its excellent quality, helps much on superior fabric production to support the face mask production and combat the COVID-19 epidemic situation.

Sino Mould, experienced in melt blown mold making with Germany technology, attaches importance to mold design, quality control, and maximize customer value.

Melt Blown Fabric Mold Steel Selection

Regarding the main part of melt blown mold steel, Sino Mould chooses SU630/DIN 1.2083 with good polishing performance, stable steel properties, and wear resistance, antirust, to ensure long time mold running.

Melt Blown Fabric Mold Head Design

The mold head of melt blown mold is one of the core components of polymer drawing forming. Design and precision directly affect the drawing length, uniformity, toughness, fineness and many other aspects. Thus, it has a decisive influence on the quality of the final production. Sino Mould design team has carried out rigorous analysis and optimization on the design, processing technology and mold treatment of the mold head to ensure the uniformity and stability of mold head discharge.

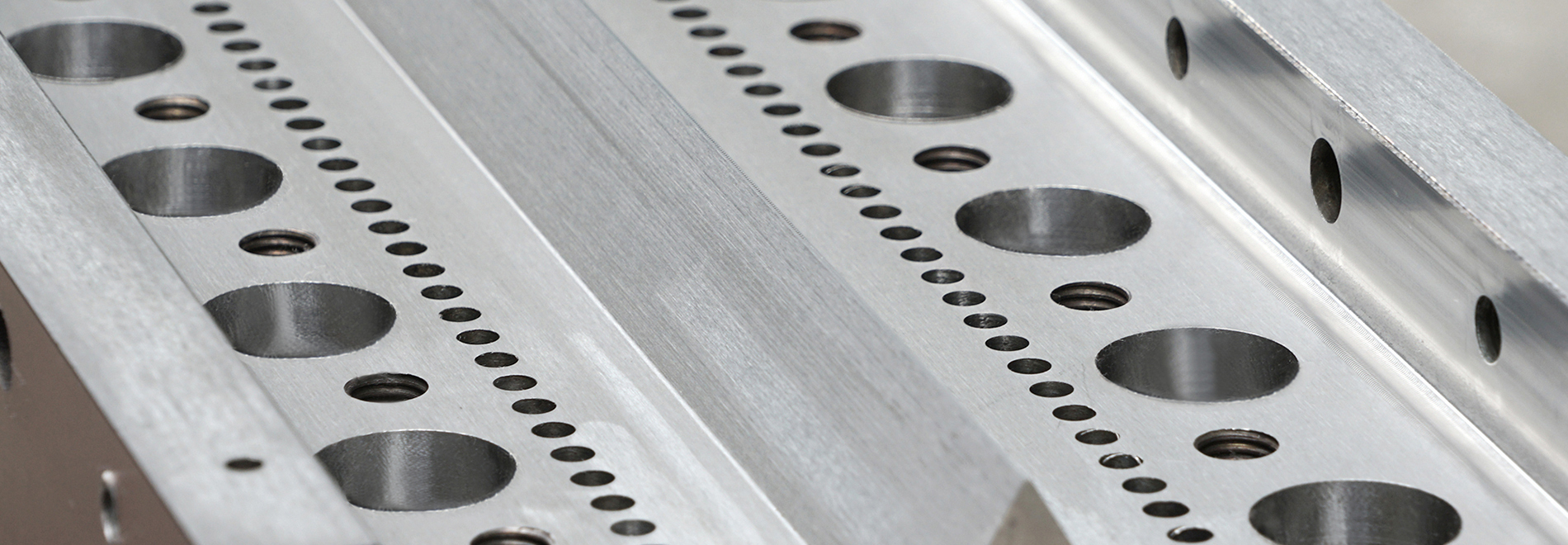

Melt Blown Fabric Mold Spinneret

The diameter of the spinneret hole processed by SINO is 0.2-0.3mm according to different cloth widths. According to the actual measurement, PP melt flows evenly in each hole, flows smoothly without blocking the hole, the fiber is softer, and the protective property of melt blown fabric is higher. The high quality processing of the melt blown mold of the core material of mask was solved effectively.

And Sino Mould applies all kinds of high-speed milling, CNC milling machines, drilling machines and other precision mold processing equipment for precision machining of the spinneret hole.

Melt Blown Fabric Mold Precision Test

After precision machining, the melt blown mold shall pass the dimensional accuracy test of QC center. Sino Mould uses hexagon three coordinate measuring instrument and joint arm measuring instrument to control the size of parts, so as to further ensure the accuracy of the whole mold.